Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date:2023-07-20 03:29:50Number of views: author:锦强矿业装备

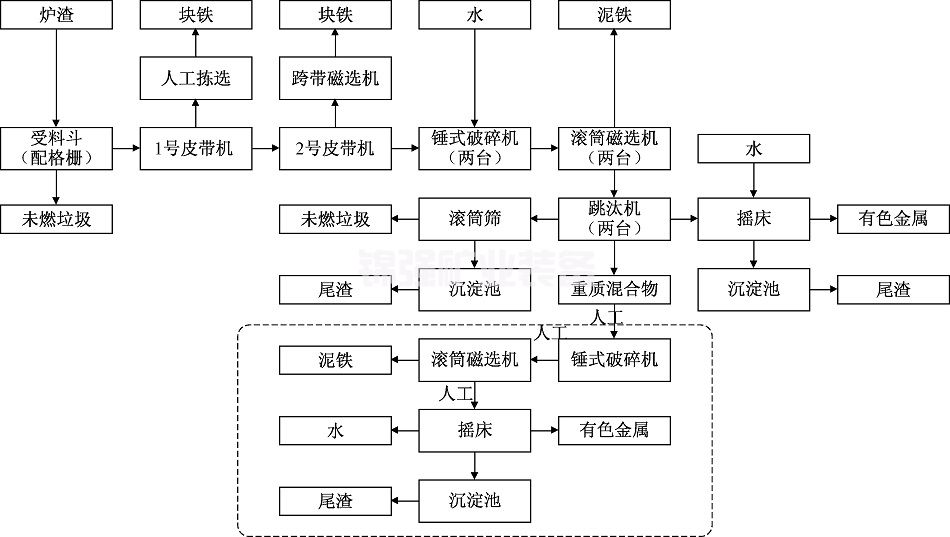

With the acceleration of industrialization, the number of power plants is also constantly increasing, and the slag generated by power plants is also increasing. Slag refers to solid waste that melts at high temperatures. Due to its high content of metal elements, the recovery and processing of slag has become an important task. This article will introduce the operational steps and precautions for the recovery and processing of metal from power plant slag.

1、 Operating steps for metal recovery from power plant slag

1. Classification of slag

Firstly, it is necessary to classify the slag and use different recycling and processing methods based on different types and components of slag. At present, common slag includes blast furnace slag, converter slag, electric furnace slag, etc. Blast furnace slag contains a large amount of iron element, which can be recovered to obtain economic benefits.

2. Slag crushing

Crush the slag to a certain degree of fineness, which facilitates subsequent sorting and processing. Slag crushing can be achieved through mechanical or chemical crushing methods.

3. Magnetic separation

uses a magnetic separator to separate the slag and separate the iron element from it. This is one of the most commonly used methods in slag recovery. Magnetic separation can recover and utilize the iron element in the slag, while also reducing environmental pollution.

uses a magnetic separator to separate the slag and separate the iron element from it. This is one of the most commonly used methods in slag recovery. Magnetic separation can recover and utilize the iron element in the slag, while also reducing environmental pollution.

4. Re-selection separation

For some metal elements that are not easily separated by magnetic separation, the method of re separation can be used. By using a gravity separator to separate the slag and separate the metal elements from it, the goal of recycling is achieved.

5. Refining and processing

For the recovered metal elements, refining and processing are also required to meet certain purity and quality requirements. Refining processing can use methods such as electrolysis and melting to process metal elements and obtain high-quality metal products.

2、 Precautions for metal recovery from power plant slag

1. The classification and composition analysis of slag are very important, and different slag requires different recovery and processing methods.

2. The crushing treatment of slag needs to reach a certain fineness to facilitate subsequent sorting and processing.

3. Magnetic separation is one of the most commonly used methods in slag recovery, but for some metal elements that are not easily separated by magnetic separation, other separation methods need to be used.

3. Magnetic separation is one of the most commonly used methods in slag recovery, but for some metal elements that are not easily separated by magnetic separation, other separation methods need to be used.

4. The recovered metal elements also need to be refined and processed to meet certain purity and quality requirements.

5. The recycling and processing of slag should pay attention to environmental issues and minimize environmental pollution.

3、 Summary

The recovery and processing of slag metal from power plants is an important task, which can reduce environmental pollution and achieve economic benefits. When carrying out slag recovery and processing, it is necessary to pay attention to the classification and composition analysis of slag, adopt different recovery and processing methods, and also pay attention to environmental protection issues. Through scientific recycling and processing methods, the resource utilization of slag can be achieved, contributing to sustainable development.

Metal recovery and processing of power plant slag

Metal recovery and processing of power plant slag