Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date:2023-07-20 03:27:43Number of views: author:锦强机械

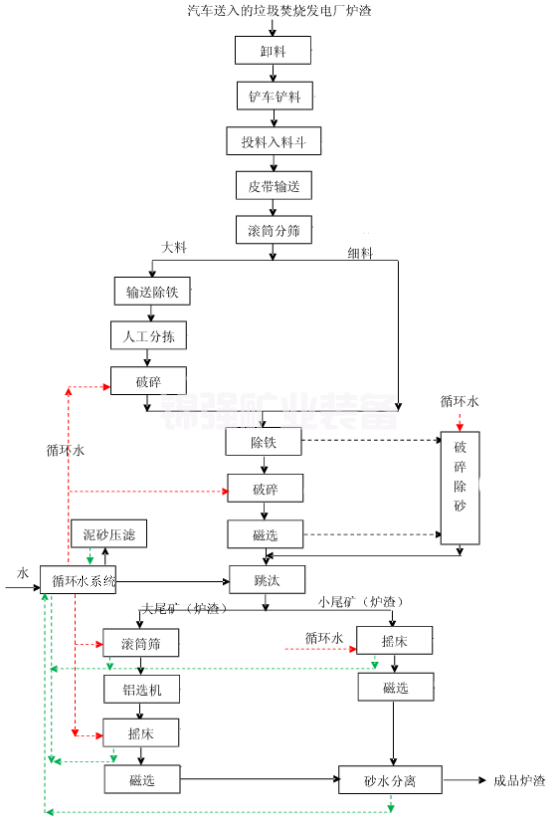

Household waste is an inevitable problem in modern cities, and a large amount of household waste is generated every year. These garbage can cause serious pollution to the environment without treatment. However, the slag in household waste is a valuable resource that can be extracted to obtain metals. This article will introduce the operational steps for extracting metals from household waste slag.

1、 Source of slag

Slag refers to solid waste generated in industries such as metallurgy and thermal engineering. The slag in domestic garbage mainly comes from Incineration plant. In the process of Incineration, a large amount of heat energy will be generated after the waste is burned, which can be used for power generation or heating. At the same time, during the combustion process, the organic matter in the garbage will be burned off, and the remaining part is the slag.

II. Composition of slag

II. Composition of slag

The composition of slag mainly includes metals, non-metals, and inorganic salts. Among them, metals are the parts we need to extract, mainly including iron, copper, aluminum, and so on. The non-metallic parts are mainly composed of oxides and silicates. Inorganic salts refer to salts of elements such as sodium and potassium.

3、 Extraction method of slag

The metals in slag are mainly extracted through magnetic separation and flotation methods.

1. Magnetic separation method

Magnetic separation method is a method of separating minerals by utilizing the adsorption of magnetic substances on minerals. In slag, iron is a magnetic substance that can be extracted by magnetic separation. The specific operation steps are as follows:

(1) Crush the slag into small particles.

(2) Place the crushed slag into a magnetic separator for magnetic separation.

(3) After magnetic separation, magnetic substances will be adsorbed on the magnetic poles, while non magnetic substances will be excluded.

(4) Remove the material adsorbed on the magnetic pole and melt it to obtain metal.

2. Flotation method

Flotation method is a method of separating minerals by utilizing the difference in specific gravity of substances. In slag, metals such as copper and aluminum are substances with high density, so they can be extracted by flotation method. The specific operation steps are as follows:

(1) Crush the slag into small particles.

(2) Place the crushed slag into a flotation machine for flotation.

(3) After flotation, metals with high density will sink to the bottom, while non-metals with low density will float on top.

(4) Remove the precipitated metal and melt it to obtain the metal.

4、 The advantages of extracting metals from slag

The advantages of extracting metal from slag mainly include the following:

1. Save resources

Extracting metal from slag can convert waste into valuable resources, thereby saving the use of raw materials.

2. Reduce pollution

Slag is a harmful waste that, if left untreated and directly discharged into the environment, can cause serious pollution to the environment. By extracting metals from slag, harmful substances can be converted into useful substances, thereby reducing pollution.

3. Increase economic benefits

Extracting metal from slag can convert waste into valuable resources, thereby increasing economic benefits.

5、 Conclusion

Extracting metals from household waste slag is a very promising technology. Extracting metal from slag can convert waste into valuable resources, thereby saving the use of raw materials, reducing pollution, and increasing economic benefits. In the future, we should increase research and promotion of this technology to better protect the environment and promote sustainable development.

Metal extraction from household waste slag

Metal extraction from household waste slag