Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date:2023-07-20 03:11:26Number of views: author:锦强选矿设备

Sulfide tin ore is an important type of tin ore, and its beneficiation process is of great significance for the extraction of tin ore. This article will introduce the operating steps of the sulfide tin ore beneficiation process and the precautions for each link.

1、 Overview of the beneficiation process flow of sulfide tin ore

The beneficiation process of sulfide tin ore mainly includes steps such as ore crushing, grinding, flotation, and selection. Among them, flotation is a key link in the beneficiation process of sulfide tin ore. The purpose of flotation is to separate useful minerals from impurities in tin ore, thereby improving the grade of tin ore. Commonly used flotation reagents include xanthate, black medicine, green medicine, etc.

II. Operation steps of beneficiation process of tin sulfide ore

II. Operation steps of beneficiation process of tin sulfide ore

1. Ore crushing

The first step in the beneficiation process of sulfide tin ore is ore crushing. The purpose of ore crushing is to break the ore into appropriate particle sizes for subsequent process operations. Commonly used crushing equipment includes jaw crushers, cone crushers, impact crushers, etc.

2. Grinding

After ore crushing, grinding is required. The purpose of grinding is to further refine the ore for subsequent flotation operations. Commonly used grinding equipment includes ball mills, rod mills, etc.

3. Flotation

Flotation is a key link in the beneficiation process of sulfide tin ore. The purpose of flotation is to separate useful minerals and impurities from tin ore. The basic principle of flotation is to utilize the adsorption properties of reagents to combine useful minerals with bubbles, thereby achieving separation. Commonly used flotation equipment includes mechanical flotation machines, air flotation separators, etc.

4. Selection

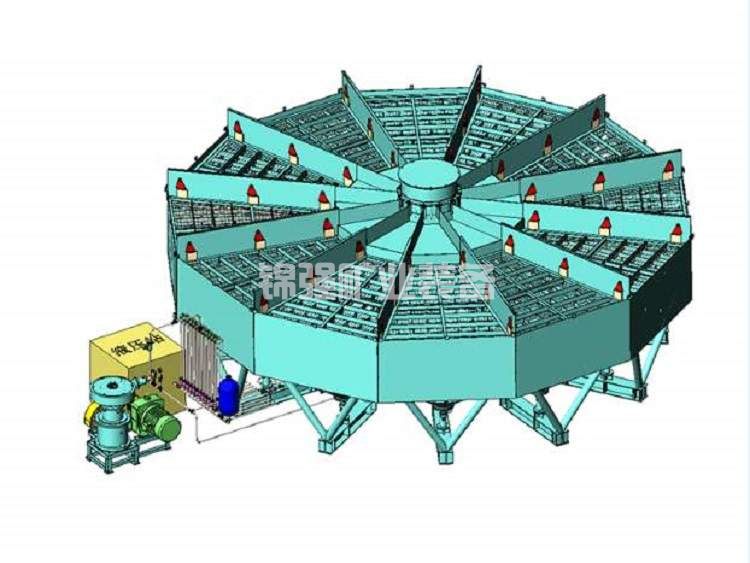

Selection is the final step in the beneficiation process of sulfide tin ore. The purpose of selection is to further extract useful minerals that have not been separated during the flotation process, thereby improving the grade of tin ore. Commonly used selection equipment includes heavy media selection, centrifugal selection, etc.

III. Precautions for the beneficiation process of sulfide tin ore

III. Precautions for the beneficiation process of sulfide tin ore

During the process of ore crushing and grinding, attention should be paid to controlling the particle size of the crushing and grinding for subsequent flotation operations.

2. The selection of flotation reagents should be based on the properties of the ore and the actual situation during the flotation process.

During the flotation process, attention should be paid to controlling the size and quantity of bubbles in order to achieve the separation of useful minerals and impurities.

During the selection process, attention should be paid to controlling the speed and inclination angle of the beneficiation equipment in order to achieve the extraction of useful minerals.

In short, the beneficiation process of sulfide tin ore is a complex process that requires strict adherence to the operating steps and attention to the precautions in each link. Only in this way can the grade of tin ore be improved and efficient extraction of tin ore be achieved.

Technological process of sulfide tin ore beneficiation

Technological process of sulfide tin ore beneficiation