Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date:2023-07-20 03:08:18Number of views: author:锦强选矿设备

With the improvement of people's living standards, the amount of garbage generated is also increasing. The disposal of garbage has always been a challenge, not only requiring a large amount of land resources, but also causing pollution to the environment. In order to solve this problem, people began to study the reuse of garbage. Extracting metal from waste slag is one of the ways to reuse it.

1、 The principle of extracting metals from waste slag

Waste slag refers to the solid waste generated in the process of Incineration. Garbage slag contains a large amount of metal elements, such as iron, copper, aluminum, etc. The principle of extracting metals from waste slag is to use physical and chemical methods to separate metal elements from waste slag.

2、 Steps for extracting metals from waste slag

1. Pretreatment of garbage and slag

1. Pretreatment of garbage and slag

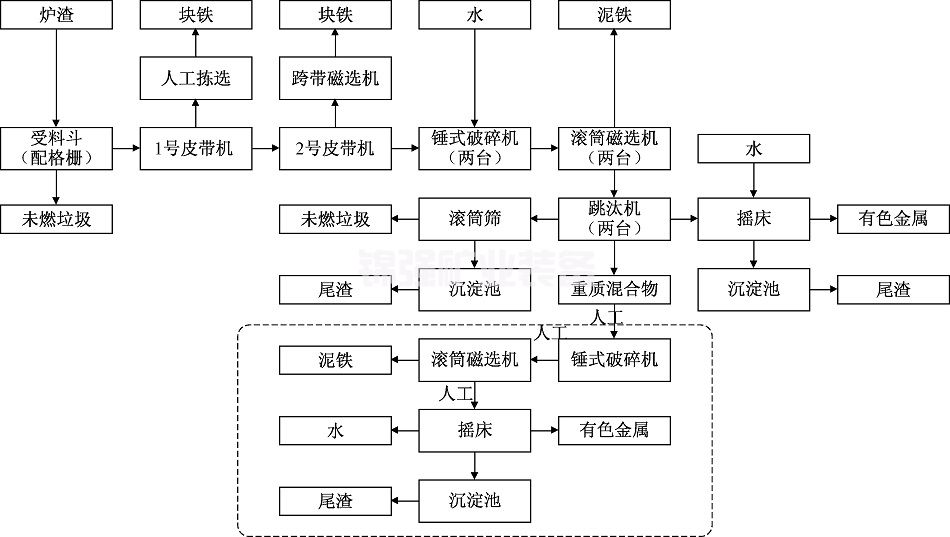

Garbage slag needs to undergo pre-treatment before extracting metal. Firstly, it is necessary to screen the waste slag and remove the large blocks of materials and impurities from it. Then, the waste slag is crushed to form a powder.

2. Heat treatment of waste slag

2. Heat treatment of waste slag

The waste slag after pre-treatment needs to undergo heat treatment. Heat treatment is the process of heating waste slag to a certain temperature, causing the organic matter and water inside to evaporate, leaving behind metal elements and inorganic substances. The temperature of heat treatment is generally above 1000 ℃, and a high-temperature furnace can be used for treatment.

3. Chemical treatment of garbage and slag

The waste slag after heat treatment needs to undergo chemical treatment. Chemical treatment is the reaction between waste slag and chemical reagents, causing the metal elements in it to undergo chemical reactions with chemical reagents and separate them. Common chemical reagents include hydrochloric acid, sodium hydroxide, etc.

4. Separation and Purification of Metal Elements

4. Separation and Purification of Metal Elements

After chemical treatment, the metal elements have been separated, but they also contain some impurities. Metal elements need to be separated and purified. There are many methods for separation and purification, such as solvent extraction, ion exchange, etc.

5. Processing of Metal Elements

The metal elements that have been separated and purified can be processed. There are many methods of processing, such as smelting, casting, rolling, etc. The processed metal elements can be made into various metal products, such as steel, copper pipes, aluminum alloys, etc.

3、 The advantages of extracting metals from waste slag

1. Resource reuse

Extracting metal from waste slag can reuse the metal elements in waste and reduce the consumption of natural resources.

2. Environmental protection

Extracting metal from garbage and slag can reduce the occupation of land resources by garbage and reduce the pollution of garbage to the environment.

3. Economic benefits

Extracting metal from waste slag can convert waste into valuable metal elements, creating economic benefits for society.

4、 Application of Metal Extraction from Garbage Slag

Extracting metal from waste slag can reuse the metal elements in waste and make various metal products. These metal products can be widely used in fields such as construction, transportation, machinery, electronics, etc.

5、 Conclusion

Extracting metals from waste slag is an effective way of reusing waste. Extracting metals from waste slag can reuse the metal elements in waste, reduce the consumption of natural resources, and also reduce environmental pollution caused by waste. The technology of extracting metals from waste slag still needs further improvement, but it has become a sustainable waste treatment method.

Metal extraction from waste slag