Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date:2023-07-20 03:05:23Number of views: author:锦强矿机

Tungsten is an important metal element widely used in the manufacturing of tungsten wires, alloys, electrodes, and other fields. The main source of tungsten is tungsten ore, so the beneficiation equipment for tungsten ore is particularly important. This article will introduce the types, characteristics, and operation steps of tungsten mining beneficiation equipment at home and abroad.

1、 Beneficiation methods for tungsten ore

There are three main beneficiation methods for tungsten ore: gravity separation, flotation, and chemical separation. Among them, gravity separation is the main method for tungsten ore beneficiation. The gravity separation method is to separate tungsten ore by gravity separation according to the density difference of tungsten ore. The flotation method utilizes the different surface properties of tungsten ore and other minerals to float tungsten ore to the water surface through bubble adsorption, thereby achieving separation. The principle of chemical selection is to separate tungsten ore using the principles of chemical reactions.

2、 Mineral processing equipment for tungsten mines at home and abroad

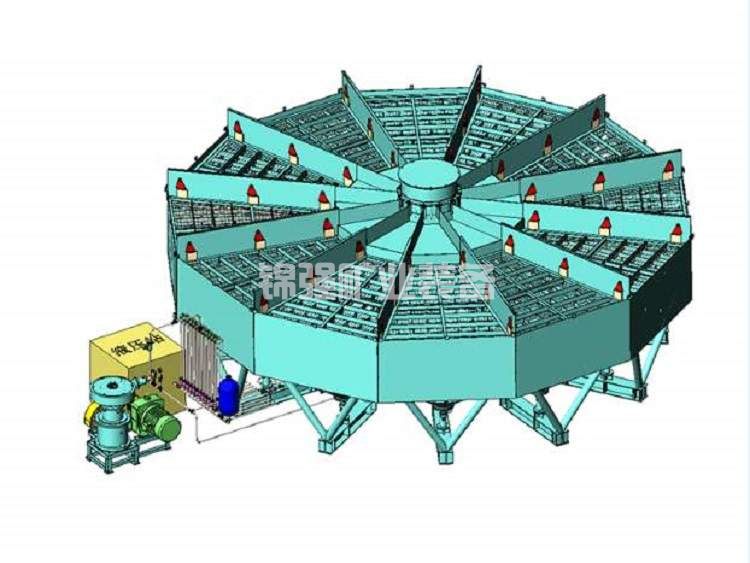

1. Re-selection equipment

The commonly used gravity separation equipment at home and abroad include gravity separators, spiral separators, centrifugal separators, etc. Among them, a gravity separator is a device that uses the power of water flow to separate ores, mainly used for rough and intermediate beneficiation in mineral processing. The spiral sorting machine, on the other hand, uses the principle of spiral to separate ores and is commonly used for intermediate and selective beneficiation in mineral processing. A centrifugal separator uses centrifugal force to separate ores, mainly used for beneficiation in mineral processing.

2. Flotation equipment

The flotation equipment mainly includes flotation machines, air flotation machines, magnetic flotation separators, etc. A flotation machine is a device that uses bubbles to float ore onto the water surface, mainly used for intermediate and selective beneficiation in mineral processing. Air flotation machines use bubbles to float ore onto the water surface, commonly used in rough and intermediate beneficiation in mineral processing. The magnetic levitation separator uses magnetism to separate ores, mainly used for beneficiation.

3. Chemical selection equipment

The chemical separation equipment mainly includes leaching tanks, adsorption towers, sedimentation tanks, etc. The leaching tank is a device that uses chemical reactions to separate tungsten ore, mainly used for intermediate and selective beneficiation in mineral processing. The adsorption tower uses an adsorbent to adsorb tungsten ore, commonly used in rough and intermediate beneficiation in mineral processing. The sedimentation tank uses the principle of sedimentation to separate tungsten ore, mainly used for beneficiation.

3、 Operating Steps

1. Operation steps of reselection method

(1) Feed tungsten ore into a gravity separator for rough and intermediate separation.

(2) Feed the selected intermediate ore into the spiral separator for intermediate and selection.

(3) Feed the selected selected selected ore into a centrifugal separator for selection.

2. Operation steps of flotation method

(1) Feed tungsten ore into a flotation machine for intermediate selection and selection.

(2) Feed the selected selected selected ore into an air flotation machine for selection.

(3) Feed the selected selected selected ore into a magnetic flotation machine for cleaning.

(3) Feed the selected selected selected ore into a magnetic flotation machine for cleaning.

3. Operation steps of chemical selection method

(1) Send tungsten ore into the leaching tank for intermediate selection and selection.

(2) Send the selected selected selected ore into the adsorption tower for selection.

(3) Send the selected selected selected ore into the sedimentation tank for selection.

4、 Summary

There are various types of beneficiation equipment for tungsten ore, and different beneficiation methods require the use of different equipment. During operation, it is necessary to select the corresponding equipment based on the specific beneficiation method and follow the operating steps. By using reasonable beneficiation equipment and operating methods, the beneficiation efficiency of tungsten ore can be improved, production costs can be reduced, and market demand can be better met.

Mineral processing equipment for tungsten mines at home and abroad

Mineral processing equipment for tungsten mines at home and abroad