Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date:2023-07-20 03:03:08Number of views: author:锦强矿山机械

Tin is an important non-ferrous metal widely used in various fields such as electronics, construction, and automobiles. In the production process of tin, beneficiation is a crucial step. The application of high-end tin ore dressing equipment can improve beneficiation efficiency, reduce waste, reduce costs, and improve product quality. This article will introduce the types, characteristics, operating steps, and other related knowledge of high-end tin ore dressing equipment.

Type of high-end tin ore dressing equipment

1. Heavy medium beneficiation equipment

heavy medium beneficiation equipment is a type of equipment that uses heavy medium to separate ores, mainly including cyclones, ball mills, flotation machines, etc. Dense medium beneficiation equipment can be used for separation according to the density difference of ore, and is suitable for separation density greater than 2.5g/cm ³ Cassiterite.

heavy medium beneficiation equipment is a type of equipment that uses heavy medium to separate ores, mainly including cyclones, ball mills, flotation machines, etc. Dense medium beneficiation equipment can be used for separation according to the density difference of ore, and is suitable for separation density greater than 2.5g/cm ³ Cassiterite.

2. Flotation and beneficiation equipment

2. Flotation and beneficiation equipment

Flotation beneficiation equipment is a type of equipment that uses bubbles to separate cassiterite and impurities, mainly including flotation machines, air flotation machines, etc. Flotation and beneficiation equipment can be used to separate ores based on their hydrophilicity, hydrophobicity, and other characteristics, suitable for density less than 2.5g/cm ³ Cassiterite.

3. Magnetic separation and beneficiation equipment

Magnetic separation and beneficiation equipment is a type of equipment that uses magnetism to separate cassiterite and impurities, mainly including wet magnetic separators, dry magnetic separators, etc. Magnetic separation equipment can be used to separate cassiterite containing magnetic substances based on the magnetic properties of the ore.

2、 Characteristics of high-end tin ore selection equipment

1. Efficient and energy-saving

The high-end tin ore selection equipment adopts advanced technology and equipment, which has the characteristics of high efficiency and energy conservation. In the beneficiation process, it can reduce waste, improve beneficiation efficiency, reduce energy consumption, and save costs.

2. High precision

High end tin ore selection equipment has the characteristic of high precision, which can perform fine sorting of ore and improve product quality. During the beneficiation process, impurities can be effectively removed and the purity of cassiterite can be improved.

3. Easy to operate

High end tin ore selection equipment is easy to operate and can be controlled and monitored by computers to achieve automated production. Operators only need to perform simple operations and maintenance to achieve efficient beneficiation production.

3、 Operation steps of high-end tin ore selection equipment

1. Preparation work

Before conducting mineral processing production, it is necessary to inspect and maintain the equipment to ensure its normal operation. At the same time, it is necessary to prepare raw materials and auxiliary materials, as well as necessary tools and equipment.

2. Ore crushing

Crush the raw cassiterite to reach the required Granularity. Crushing can be done using equipment such as jaw crushers and cone crushers.

3. Ore classification

Classify the crushed cassiterite and send it to different beneficiation equipment for sorting. Grading can use equipment such as sieving and hydrocyclones.

4. Mineral processing and sorting

According to the properties of the ore and the characteristics of the beneficiation equipment, corresponding beneficiation and sorting are carried out. During the beneficiation process, monitoring and adjustment are necessary to ensure that the beneficiation effect meets expectations.

According to the properties of the ore and the characteristics of the beneficiation equipment, corresponding beneficiation and sorting are carried out. During the beneficiation process, monitoring and adjustment are necessary to ensure that the beneficiation effect meets expectations.

5. Product Collection

Collect and process the products after beneficiation and sorting to achieve the required product quality and specifications. Collection can be carried out using equipment such as conveyor belts and bucket elevators.

4、 Conclusion

High end tin ore dressing equipment is an indispensable part of tin ore dressing production. By adopting advanced technology and equipment, mineral processing efficiency can be improved, waste can be reduced, costs can be reduced, and product quality can be improved. During the beneficiation production process, it is necessary to pay attention to the maintenance and operation of equipment to ensure its normal operation. At the same time, monitoring and adjustment are needed to achieve the expected beneficiation effect.

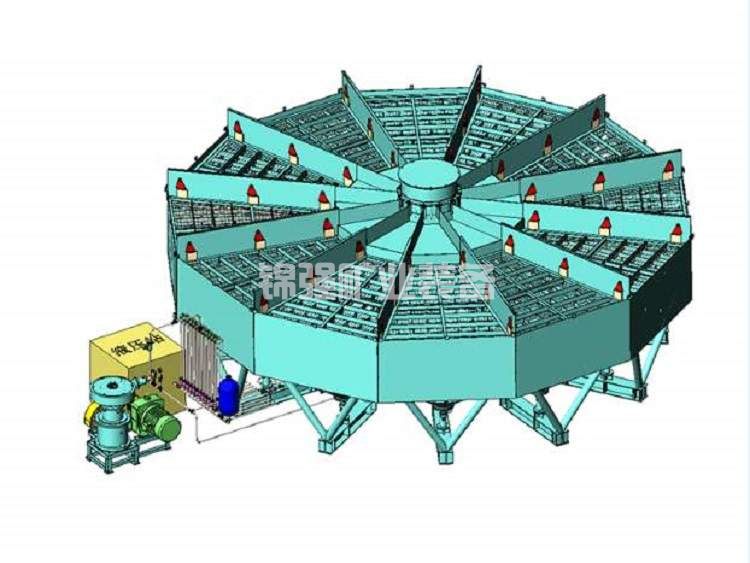

High end tin ore selection equipment

High end tin ore selection equipment